Differentiate or Die – such is the title of the book by J.F. Trout, and also the idea adopted by Recutech CEO Filip Hazuka in his business. The pioneering approach is evident throughout the ten-year existence of the Pardubice-based company, a leading developer and producer of counterflow heat exchangers.

In his interview for TRADE NEWS six years ago, the manager admitted that he had always been a bit of a rebel and that he also runs the company in his own way. "That’s still true. People don't change and I won't either. Our growing results confirm we’re on the right track."

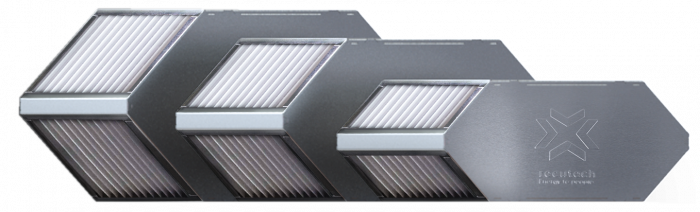

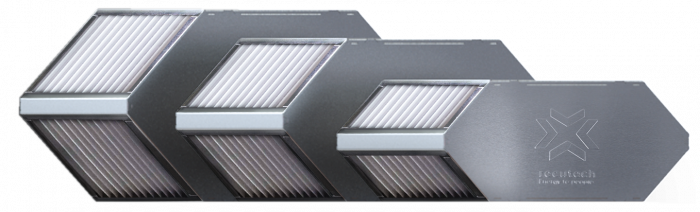

The motto "Differentiate or Die" somewhat resembles the marketing warfare theory, also co-proposed by Jack Trout. However, Filip Hazuka argues that in reality this means that customers must know why they should buy heat exchangers from Recutech and not from competitors. "Our main strengths are 100% quality, long-term partnership, guaranteed tightness of all heat exchangers, the widest range possible and product innovations."

Recutech have based their entire product portfolio on innovation. At first, they developed their products in close cooperation of the company's R&D team with the Technical University of Liberec, which has research and technological know-how and computing facilities. "In this cooperation, we have learned many things from each other, but we have also found some limitations. The Czech grant system is set up in such a way that an interesting topic or idea is often enough, and the outcome is not that important. Universities have often adapted to this system. They use subsidies as another source of financing, and sometimes they no longer see it as priority to put research results into practice and help develop a competitive product. However, for companies, it’s all about marketability of the end product.

Our company has therefore had to factor this in. We have gradually created our own R&D platform, which we are trying to expand and build other projects based on the acquired know-how. These days, we let universities take part only in specific tasks defined by us, which fit into our R&D strategy," Filip Hazuka points out, concluding there are some bottlenecks in the translation of research into business practice.

Quality is either there or it isn't

In 2016, Recutech was the only company in the world that measured and guaranteed exchanger tightness for all of produced ones. Competitors got inspired, and it has become more or less standard practice in the industry ever since. That's why the company knew it was necessary to come up with something new.

"We still maintain our reputation of a partner that never compromises quality. There is only one type of quality. It is either there or it isn't. There is nothing in between. Plus, development must always go forward. This year we are launching a new counterflow enthalpy heat exchanger, whose parameters make it unique and best in the world. It achieves market-standard humidity efficiency, while securing at least +10% temperature efficiency. Unlike competitor products, it is non-flammable, pressure-resistant and more airtight. We are currently working to get a worldwide patent."

Strong in Scandinavia

The global energy saving trend, quickly embraced by advanced economies in particular, is something heat exchanger manufacturers can leverage. Recutech's export scope reflects this, too. Besides the European market, the company also delivers to the US, Canada, Australia and New Zealand. They have a strong presence particularly in the sophisticated Nordic markets.

"There are a few reasons for that. First of all, environmental protection and energy saving have long been seen as paramount in the Nordics. On top, there are longer winters and lower temperatures, so there is quick ROI of using our counterflow heat exchanger in recovery ventilation units. Last but not least, people in the Nordics prefer high product quality over price, which is our advantage. Scandinavia currently accounts for around 25 percent of our turnover."

First come, first served

The company’s performance has long been based on automation and high efficiency. Production has gone up to the current volume of 190,000 exchangers per year. Their production line is state-of-the-art and tailored to the types of exchangers produced. However, the "just in time" based production process was negatively affected by global supply chains disruptions. Filip Hazuka admits that these issues have forced some changes in the approach and organisation of the production model. "Previously, price played a major role in customer decisions. In times of global crisis, though, delivery time has become the most important factor. We are therefore forced to keep some key components in stock, even in larger quantities."

Robotisation – planned and necessary

Recutech had a robotised workplace and computer-controlled operation already back in 2016. Are robots a game changer for Czech industry? "We carry on with robotisation, but we don’t do it everywhere or at any cost. It must be purposeful. We always compare the performance between the human and the robot and consider whether the robot is worth it. Previously, a simple cost comparison was enough. Today, we are also limited by labour shortage.

It is precisely because of the lack of qualified workforce that we sometimes prefer a robot, even though humans are less expensive.

All machinery is controlled by computers and connected to the Manufacturing Execution System. The system collects data monitoring machinery efficiency and production performance. Data evaluation is used for further optimization. The system is connected to the ERP system, which enables the cooperation of production activities with logistics, storage, purchasing and shipping.

Company awards

Filip Hazuka's approach is also conveyed to staff relationships with the company and within the team. But at first it was not as easy to inspire a greater initiative among the staff and strengthen their identification with the company.

"They got used to the IZRI system (innovate, improve, implement and cash in) system relatively quickly, and today they can think about their work in a wider perspective and come up with suggestions for improvement themselves," the CEO points out. After all, for his excellent approach to employees and their continuous development, he won the Czech Goodwill Corporate Oscar award in the Made in Czechoslovakia category. The application was submitted by one of Recutech employees.

"The whole company is built on people. That is, a team that does its work not only because they get paid for it, but because each member enjoys it and believes in what they do. I would say that our informal relationships are also built on mutual trust, respect and, in many cases, friendship. That is the key to success.”

Written by Věra Vortelová and Jana Jenšíková

Photo credits: Recutech