The Náchod-based producer of electric motors overcame the great crisis of 1933, nationalization fifteen years later as well as a major shift in company management in 2002. ATAS is currently working to manage the crisis caused by the war in Ukraine. Germany has always been the company’s biggest trading partner, and this is where they still export the most. When talking to the chairman of the board of directors Otto Daněk, we soon find out where the success of ATAS comes from: they focus on custom solutions. That's why the company keeps winning in today’s increasingly competitive environment on a global scale.

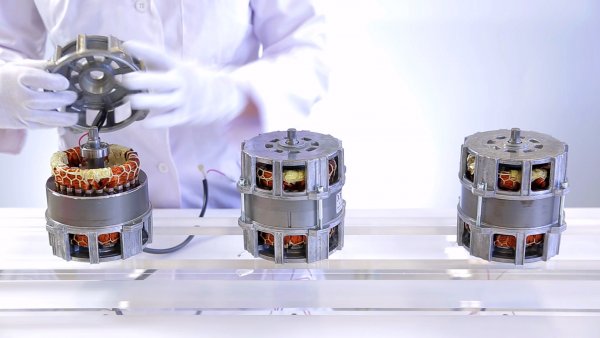

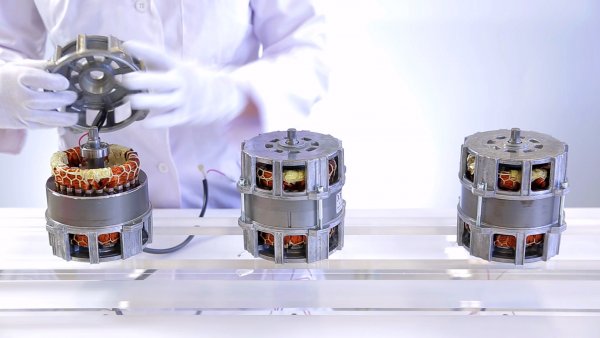

"More than 95 percent of our production consists of so-called customer motors. Almost every single motor we produce has its customer defined in advance and is intended for a specific machine. 80 percent of our products are exported abroad, as we have customers in sixty-five countries, and other motors go abroad indirectly as part of our Czech customers’ final products. All in all, there are almost no so-called over-the-counter motors in our portfolio," explains the company chairman, who has managed ATAS for twenty-two years.

"Moving forward, we can assume that due to energy prices, development will be moving towards 'smart' motors, i.e. motors with electronic commutation. The current demand for these engines is not as high as we would like because of the price. But we are ready for this already, because whoever is ready won’t be surprised when the demand increases." These motors have a balance of power and consumption, which means that the motor consumes only as much power as it needs to do the work required. There is not even a partial conversion of energy into heat as with typical engines.

A century-long history

ATAS has been active for almost a hundred years and has passed several important milestones during its existence. "The company was founded in 1928. Since it was created one year before the global crisis, which gradually spread to Europe, I’m sure that the founder Mr. Taichman must have been a great manager and launched the company very well, because otherwise it would not have survived."

Reportedly, everything looked rosy in 1928, and market analyses showed that there were no engine manufacturers in Czechoslovakia. The crisis that came to the country five years later brought many problems to both employers and employees. But despite of all that, the company still prospered and had customers. Baťa was the biggest customer back in 1933.

This was followed by the Nazi occupation in 1939, nationalization in 1948, Soviet occupation in 1968, "divorce" with Slovakia in 1993 - the Náchod-based company overcame all that without any major issues. Then 2002 proved to be a positive milestone, which saw a fundamental shift and also stabilization in the company management.

Many experienced managers agree that the main prerequisite for a successful company is a good team, which must include hard-working professionals in all processes. The team has to know the gradual goals and look for the best way to achieve them and set the deadlines when they should be achieved. "There is one more key component, which sometimes get neglected these days – empathy and humanity. If you add just a little of this ingredient to the mix, it adds taste and digestibility to what the company is cooking," adds Otto Daněk.

Empathy and humanity are key components in our team.

Investments must be smart

Acquisition of new modern machines is a necessity any manufacturing company that wants to be successful in the long-term. ATAS has recently purchased state-of-the-art motor winding technology and machining centers. With these machines, they are looking to achieve an even higher quality of their motors and multiply their work productivity. The crisis caused by the war in Ukraine has brought about a huge increase in energy prices. The company will therefore put a lot of emphasis on energy savings and production.

"Most European countries are now trying to shift to sources that do not come from Russia. Of course, this is no easy task, as confirmed by international trade data. Gas is causing massive problems in the Czech Republic: gas prices here are much higher compared to the rest of the EU, not to speak of the US. This is obviously a huge competitive disadvantage," Otto Daněk explains. He goes on to give a specific example: "Recently we were looking for a supplier of components made of grey cast iron, which is a relatively energy-intensive product. We approached three German companies, three Czech companies and one from Switzerland... and the Czech ones were the most expensive. High energy costs are pushing us to the tail end. And that's a big problem. The Czech Republic is already losing its competitive edge and, unfortunately, for now I don't see anyone listening to us too much."

Germany has always been our biggest partner

Almost 90% of ATAS' exports go to Germany every year, mainly to its southern part - Bavaria and Baden-Württemberg. The company has been cooperating with Germany for several decades, and the current majority shareholder and largest customer ebm-papst Mulfingen also comes from Germany. ATAS’ exports to this territory have more than doubled since 2003. Meanwhile, exports to Austria have increased more than seven times over the same period, although its volume is much smaller compared to Germany.

"The crisis today is palpable not only in the Czech Republic, but also in Germany, and demand is going down. It really is true what they say that whenever Germany gets a cold, Czechia gets a bad sore throat. As I said, we depend on this country for seventy percent, while the whole Czech Republic for about thirty-two percent. Whenever something is going on in Germany, it is always a big challenge for us – whether positive, i.e. coming from high demand, or negative, when there is a decrease in demand."

In business, if you don’t look for new markets, you are doomed to fail.

In business, it is true that if you don’t look for new markets, you are doomed to fail. However, this is now difficult with the crisis caused by the war in Ukraine. "The situation was already made hard by the covid pandemic, as many components imported mainly from Asia started to be in short supply. The soaring prices of these components had a very negative impact on product prices - at times, industrial inflation was between twenty-five and twenty-eight percent, which was caused not only by energy costs, but also by the huge increase in these prices. For example, we used to buy copper wires for five euros before the conflict, while today we buy them for eleven euros. Aluminium was for 2.40 euros, and now it is for 6.50, and that’s just two examples."

Otto Daněk, Chairman of the Board of Directors of ATAS Elektromotory Náchod. In his career, Mr. Daněk has saved five major Czech industrial plants with a total of approximately 10,000 employees from bankruptcy. He has managed ATAS for 22 years. Mr. Daněk steered the company out of economic problems in the early 2000s and successfully guided it through the tough periods of 2008-2009, 2013-2014 and 2019-2021. He is now facing another challenge to lead the company through the crisis created by the Russian aggression in Ukraine.

Otto Daněk, Chairman of the Board of Directors of ATAS Elektromotory Náchod. In his career, Mr. Daněk has saved five major Czech industrial plants with a total of approximately 10,000 employees from bankruptcy. He has managed ATAS for 22 years. Mr. Daněk steered the company out of economic problems in the early 2000s and successfully guided it through the tough periods of 2008-2009, 2013-2014 and 2019-2021. He is now facing another challenge to lead the company through the crisis created by the Russian aggression in Ukraine.

Our future plans were thwarted by the war. Joint venture in Lviv not in sight yet

The war in Ukraine has had horrible impact on everything. It has thwarted hopeful plans and forced many individuals, companies and countries to seek new paths. ATAS chairman reveals, "Our intention was to start working on a joint venture in Ukraine in 2022. We wanted to move part of our production to Lviv to make it more economically efficient. We were all set and supposed to sign the contract in March. Well, we know what happened in February. Although Lviv is close to the Polish and Slovak borders, it is also being bombed and attacked by drones, so it is in danger. We are in touch with the director there. Thankfully, he and the employees are still alive, so as soon as the situation calms down, we would like to get back to this idea."

Like many other Czech managers, Otto Daněk also realizes that we now need to open new markets in less common territories where we used to be established in the past, such as Latin America, Central, North or South Africa, where there are relatively poor countries that are rich in commodities. "In order to succeed in these regions, we need to be there all the time and know the right people. More state support would help here. Our government could mediate some 'barter' deals for example," the chairman concludes.

Written by Martina Hošková a Jana Jenšíková

Photo credits: archiv ATAS elektromotory Náchod

Where are ATAS motors used?

They serve reliably in shipping containers, where they air condition the space and blow gas inside so that fruit ripens during its transport to Europe. They are also used in cleaning technology (cleaning halls, airports or roads), wind power plants (cooling generators) and airplanes (air conditioning, seat movement, toilet flushes or fuel transfers). Field hospitals are another use case, as ATAS motors keep the tents in a taut position even without tent stakes and they also keep the air inside clean via excess pressure. Other use cases include trains (door location), labs (mixers), bicycles (drive units), means of transport for the disabled (stair climbers), large printers (paint mixing), hairdryers, solid fuel boilers, drink coolers, air conditioners, dental drills, robots, combine harvesters or even hand tools.